Preface

This publication is split into four chapters, each starting with a general introduction to packaging, its functions and the current legislation surrounding packaging. This converges in a description of the recycling process for packaging made predominantly from paper, aimed at helping to define guidelines for designing paper and board packaging for recycling purposes. The structure has thus been devised to address the needs of designers and businesses, highlighting factors requiring attention that have led to the design guidelines put forward.

The first chapter describes paper packaging, setting out how it is classified, its distinctive functions, and relevant standards in force.

The second chapter shows the types of materials used for paper and board packaging, describing their main properties and applications in the market.

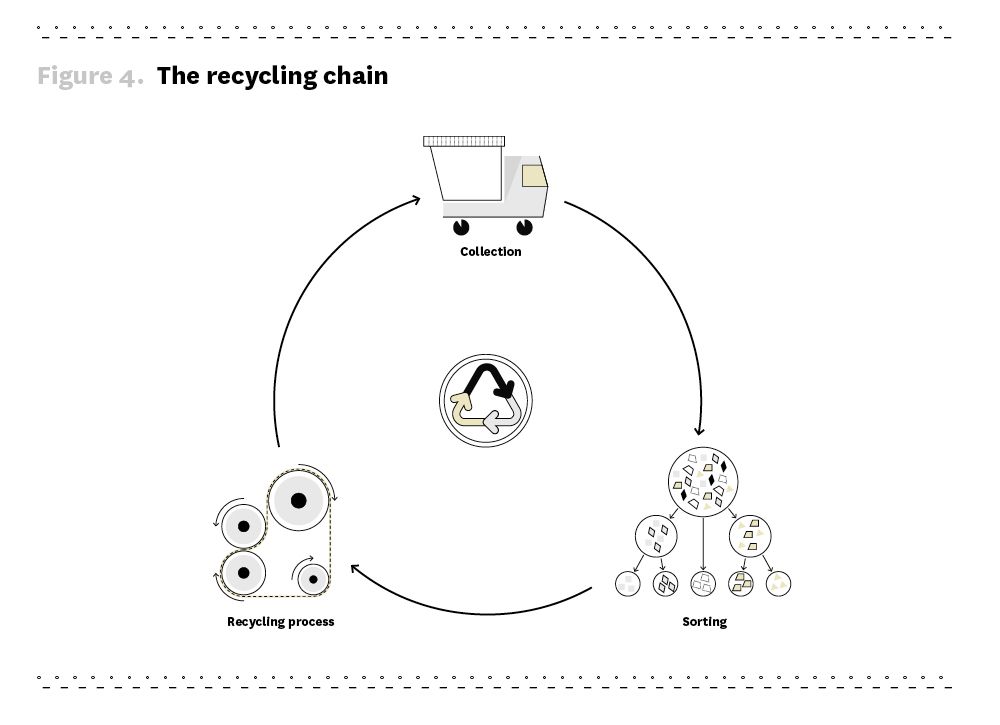

The third chapter describes the recycling chain for materials made predominantly from paper, illustrating the various stages: separate collection, sorting and paper mill recycling.

The fourth and final chapter presents guidelines for the design of packaging made predominantly from paper that is easiest for the paper mill to recycle. These guidelines provide designers and technicians with a checklist designed to be used both in packaging design and development, and as a potential assessment tool for identifying what room there is for improvement.

The information provided herein does not claim to cover each design solution individually or to be exhaustive. Instead, its aim is to highlight critical factors within the packaging sorting and recycling process in order to set the reader on a path of increased awareness and facilitation surrounding the above-mentioned activities.

Furthermore, the guidelines set out herein refer to the recycling situation in Italy. It is worth bearing in mind that every EU country is free to set its own rules within its national boundaries provided that they comply with the requirements laid down by the EU itself, meaning that certain parameters that apply to Italy may not apply to other countries.

It is also worth noting that certain guidelines may stem from specific factors within the recycling chain that, in turn, may be of an organizational or technological nature, without distinction: consequently, the guidelines put forward herein should be regarded as place and time specific, pertaining as they do to the current situation in Italy. The eco-design efforts of businesses in Italy - introduced with the Aticelca assessment system - reflect the country's wealth of recycling plants and the fact that they are used extensively: it is worth pointing out that this is not such a given in other countries characterized by a lack of infrastructure.

In light of technological progress and developing dynamics within the recycling chain, the guidelines provided herein will be updated by CONAI on a regular basis with a view to ensuring that they continue to provide an up-to-date reference resource, in line with the evolution of packaging placed on the market for consumption, and innovations associated with the recycling process: namely the whole waste collection, sorting and recycling procedure.

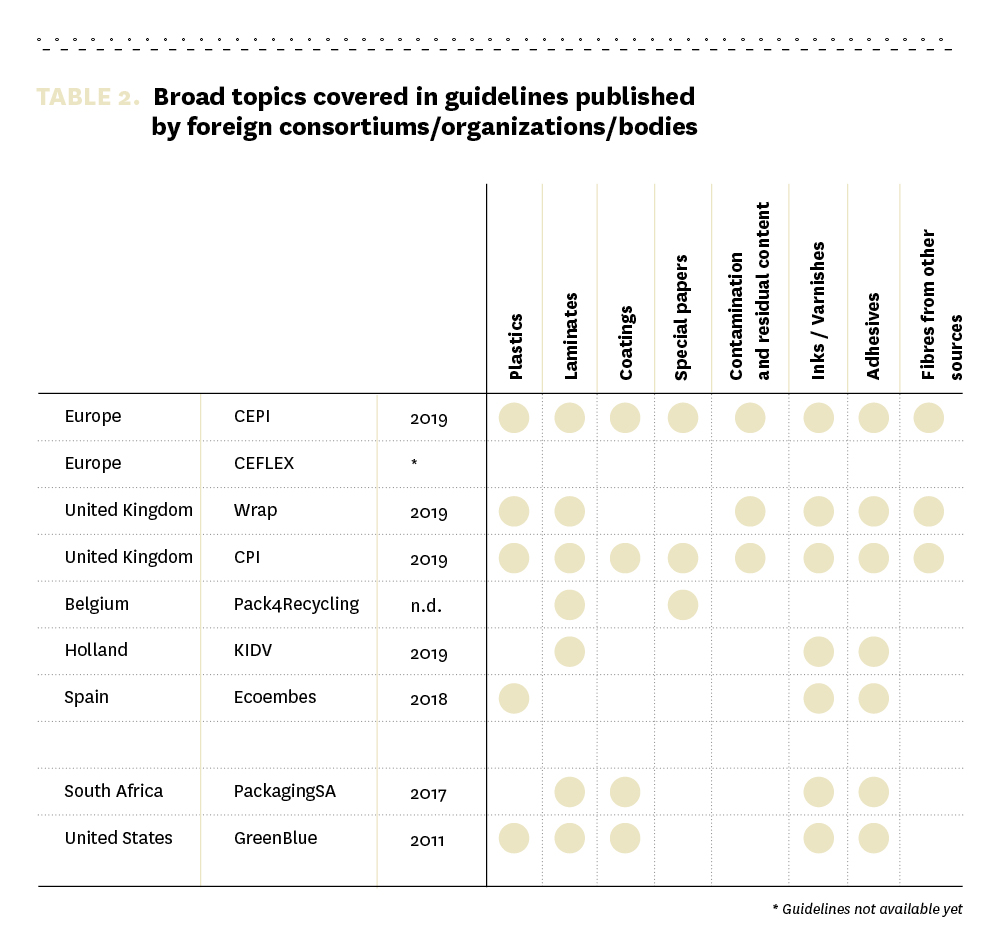

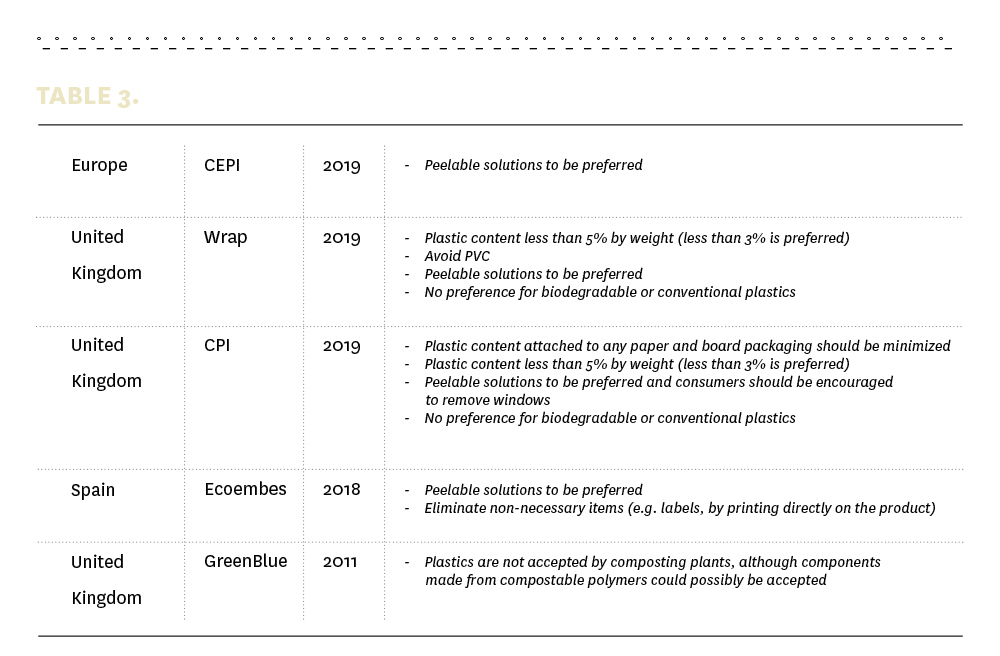

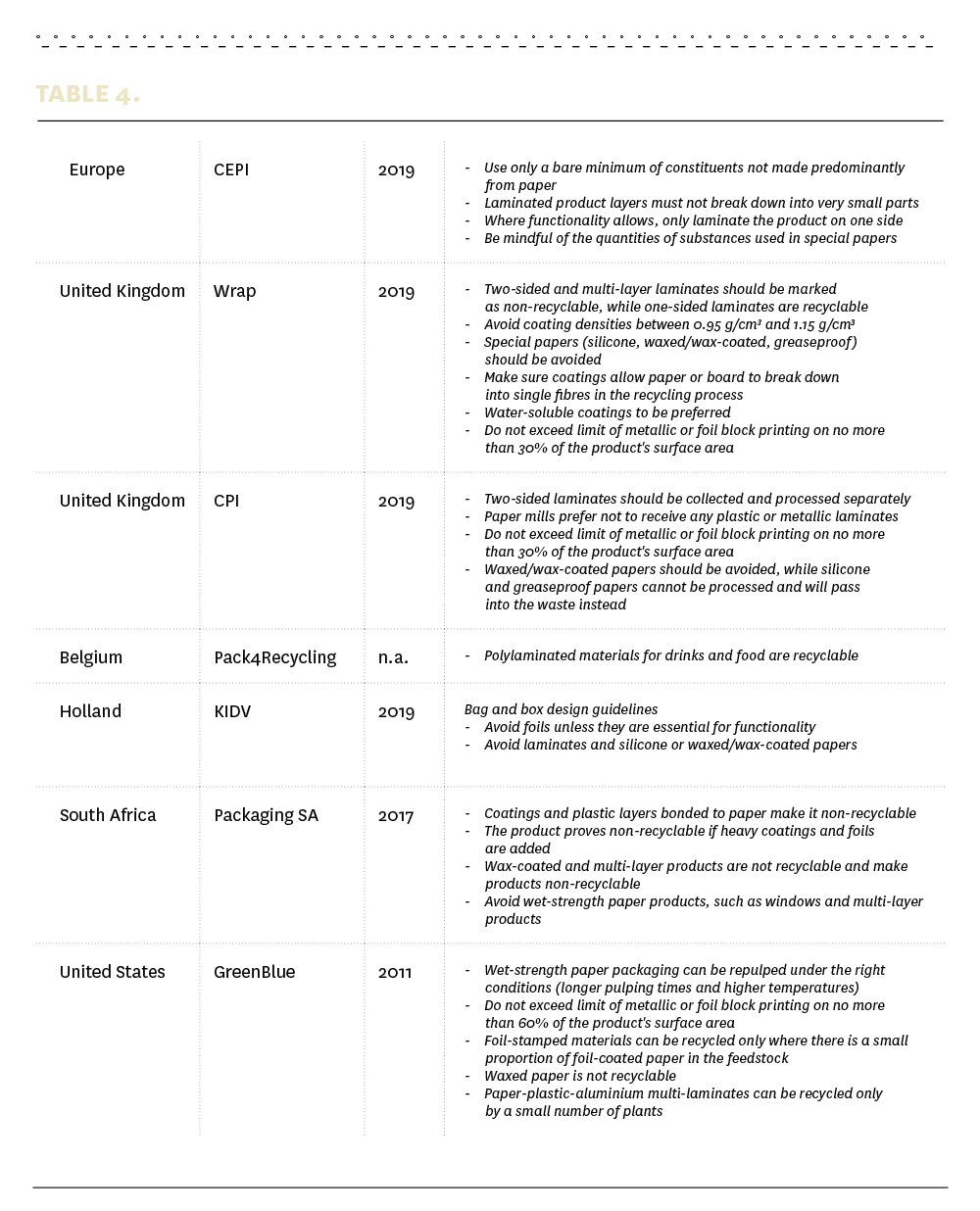

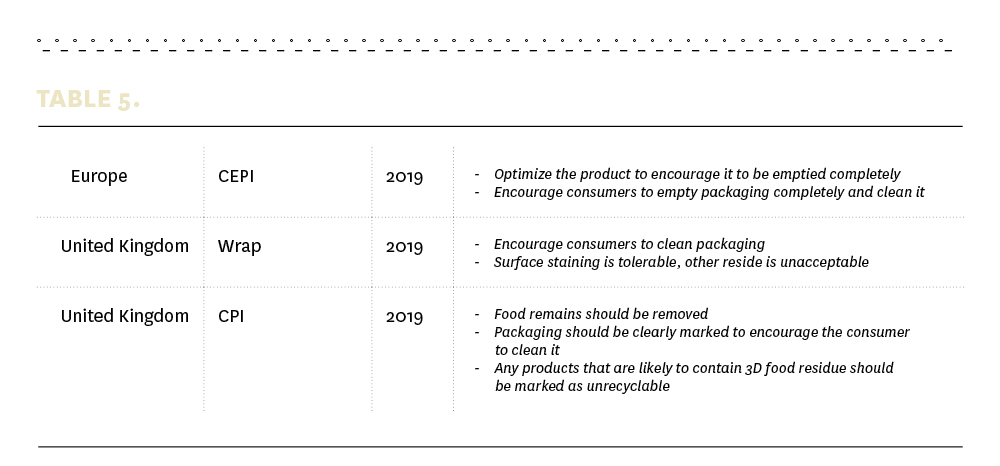

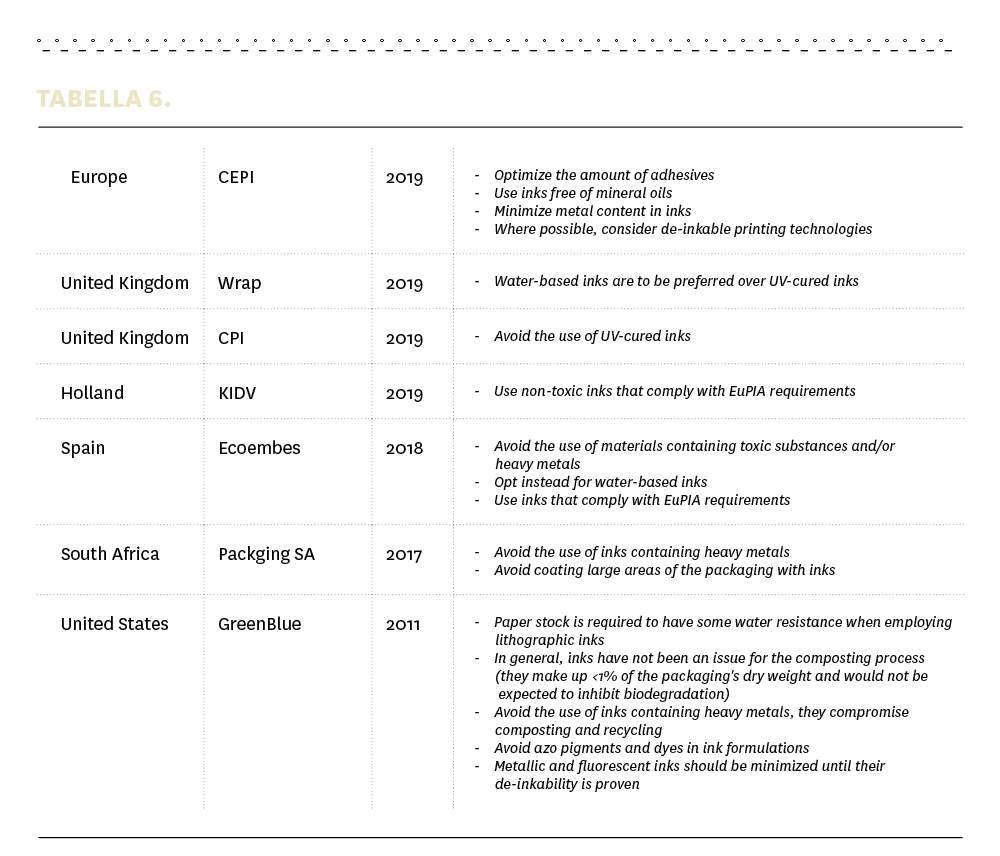

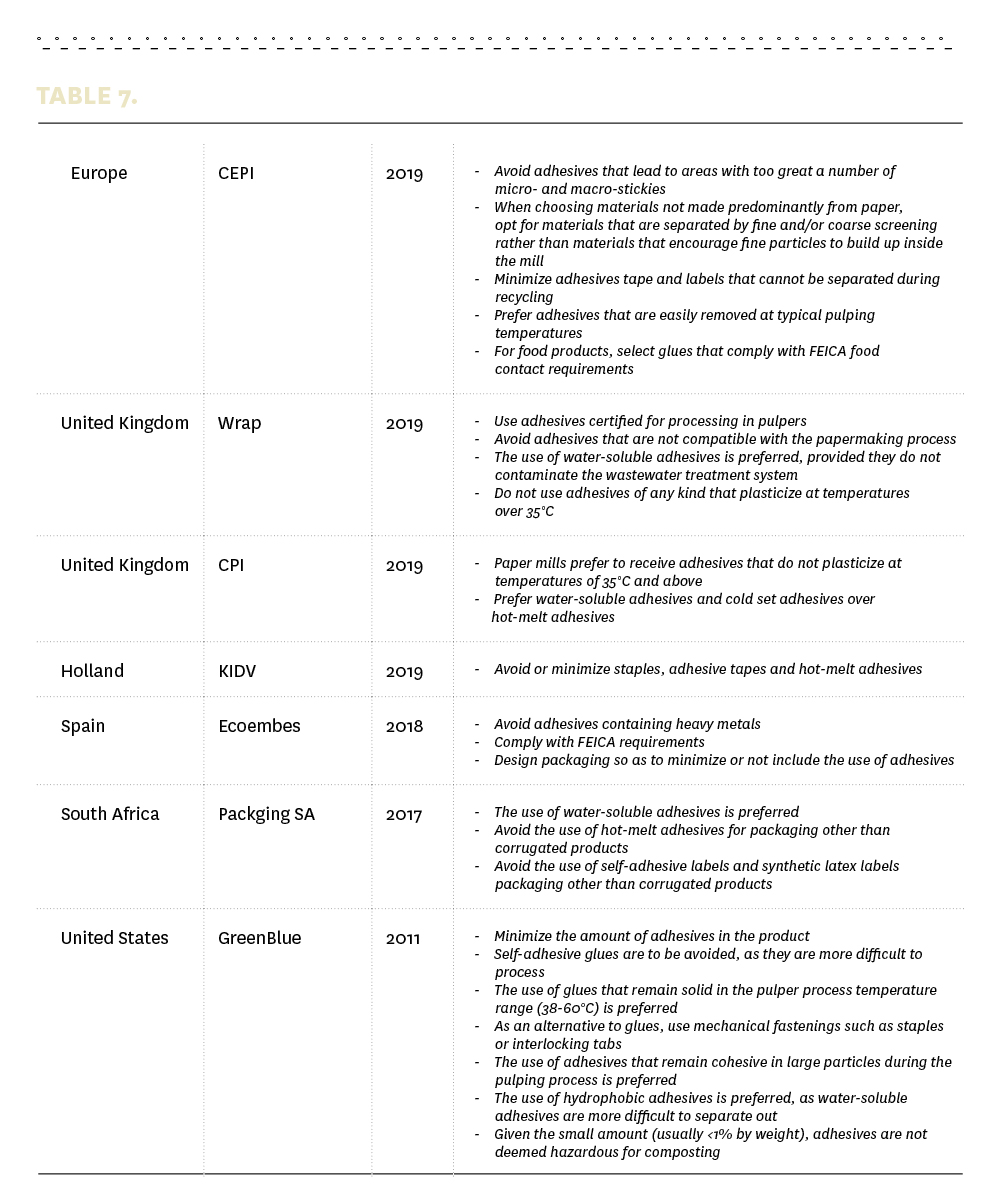

There are multiple organizations in Europe that have published guidelines to facilitate the recycling of packaging made predominantly from paper. Particularly worthy of note are initiatives by: CEPI (Confederation of European Paper Industries) - based in Belgium, but operating Europe-wide; Wrap and CPI (Confederation of Paper Industries), both operating and based in the UK; the Dutch institute KIDV; and Ecoembes, which operates in Spain.

If we expand our search to take in the rest of the world, the (by no means exhaustive) list of bodies promoting good practices includes such names as Packaging SA in South Africa; GreenBlue, which covers the US; and Paper Recycling Promotion Center (PRPC), which operates in Japan.

Alongside each of the critical factors identified, this document also gives a useful summary of what other guidelines have already been defined at an international level.

Introduction

Objectives and purposes of the guidelines

This document is part of the Pensare Futuro project, which comprises a series of initiatives developed by CONAI on preventing the environmental impact of packaging. More specifically, the document adds to the series of prospective guidelines, compiled on the www.progettarericiclo.com website.

The Consortium - whose objectives include championing a culture of environmental respect among businesses through measures designed to make packaging increasingly sustainable - promotes seven so-called prevention levers, i.e. eco-design measures aimed at reducing packaging's environmental impact upstream:

- Saving raw materials;

- Use of recycled/recovered material;

- Re-use;

- Facilitation of recycling;

- Logistics optimization;

- Simplification of the packaging system;

- Optimization of production processes.

This document addresses the Facilitation of recycling lever and aims to serve as a tool for designers planning to develop, upstream, packaging with the potential to convert its end-of-life waste into a resource.

More specifically, the document focuses on packaging made predominantly from paper, highlighting factors that may require attention during recycling and relevant opportunities to address them with solutions. In compiling this document, we are fully aware that the sheer variety of packaging found in the market makes it impossible to look at every single solution adopted by different businesses individually: hence, we will be providing what we hope is an as comprehensive as possible overview.

Packaging

SOME HISTORICAL BACKGROUND

The history of packaging is deep rooted and can be traced back to the advent of man on Earth. While ancient man rarely ate his catch on the spot, the time between procuring food and eating it was very short, but he still needed a way to carry and preserve his bounty.

Over the course of the centuries, packaging has been shaped by various influences, due to cultural changes and the evolution of consumer habits. Early containers made from natural materials, such as leaves, bamboo, shells and hides, were joined over the years by metal and ceramic containers, with the later addition of fabric, wood and paper.

The story of packaging - as we know it today - dates back to the second half of the 19th century: industrialization and the birth of the consumer society resulted in packaging being recognized for its corporate branding potential.

Starting in the early 20th century, packaging was the subject of much innovation in terms of both technology and materials, with the development of moulded glass, cardboard, metal and plastic packaging. It wasn't until after World War II that disposable packaging became popular, largely thanks to the advent of mass retail outlets.

Add to this the phenomenon of market globalization driven, above all, by digital technologies, and we start to understand how packaging has come to pack such a strong punch as a communication vehicle for businesses, and how it has become a vitally important branding tool to help them stand out in an increasingly competitive market. Consequently, packaging has come to be recognized for its communicative role.

Recently, widespread interest in sustainability aspects has become a key driver in packaging: these concepts have served to stimulate research to develop new processes and solutions that, thanks to the transfer of industrial technology, have paved the way for a new variety of products to make it onto the market.

THE FUNCTIONS OF PACKAGING

According to the relevant legislation in Italy (D.Lgs 152/06, Art. 218), packaging means “the product, consisting of materials of any kind, used to contain certain goods, from raw materials to finished products, to protect them, allow their handling and their delivery from the producer to the consumer or user, ensure their presentation, as well as disposable items used for the same purpose.”

Packaging is thus required to fulfil four functions:

- It must contain the product, holding the contents to be used by the consumer;

- It must protect the contents from external factors, such as mechanical action (impact, contact with other external objects), as well as from contamination by chemical agents (water, moisture, air, etc.), so that quality remains unchanged over time, wherever the contents end up;

- It must allow goods to be handled easily by the various users making up the distribution network, from the manufacturer all the way through to the consumer;

- It must present the goods to the consumer in an attractive way, making it an added value and playing a communicative role by transferring information from the manufacturer to the user.

How packaging is classified

Packaging has evolved over time, growing in complexity. Various factors have contributed to this evolution, including developments in the world of communication, technological processes and materials.

It is these materials that have broadened the range of possible applications and led to expansion into new product sectors. This new direction has prompted design, product innovations and material science and technology to interact, undeniably becoming both the cause and effect of these changes.

While, until fairly recently, the main purpose of packaging was to protect contents from external contamination, the current use of functional materials and new technologies has spawned a new category of what has been termed smart packaging, in which a material, a surface treatment or a technology are used to add to the packaging's functionality.

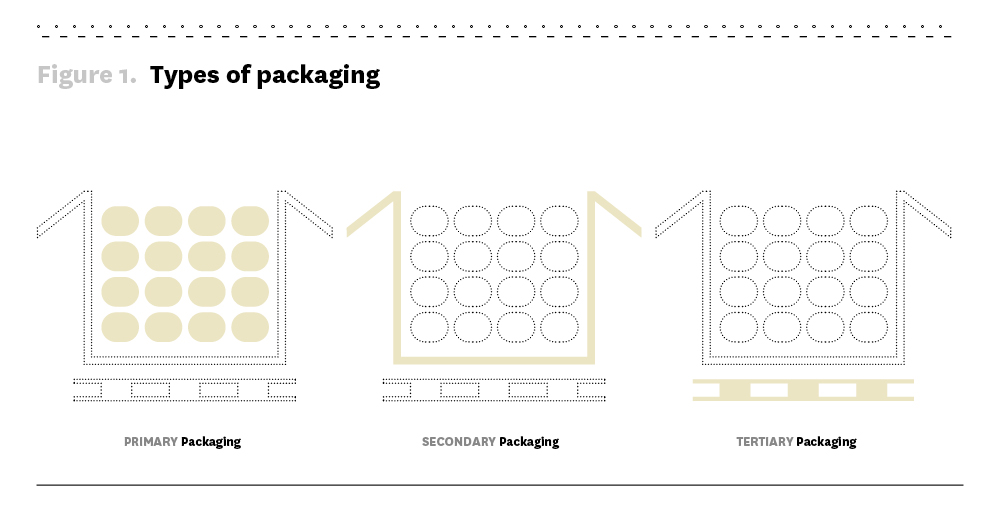

Before we go any further, now would be a good time to explain the differences between existing types of packaging:

- Sales packaging or primary packaging: packaging in contact with the product that constitutes a sales unit to the user or consumer at the point of sale;

- Grouped packaging or secondary packaging: packaging conceived so as to constitute, at the point of sale, a grouping of a certain number of sales units, whether the latter is sold as such to the user or consumer, or whether it serves only as a means to replenish the shelves at the point of sale. It can be removed from the product without affecting its characteristics;

- Transport packaging or tertiary packaging: packaging conceived so as to facilitate handling and transport of a number of sales units or grouped packaging of goods - from raw materials to finished products - in order to prevent their physical handling. In addition, tertiary packaging is intended to minimize transport damage.

Examples of paper-based primary packaging include shoeboxes, egg cartons, bread bags, and fruit juice cartons, as they fulfil the function of protecting and containing the goods that the consumer will then use directly.

Secondary packaging, on the other hand, includes the boxes that online purchases arrive in, supermarket display boxes, and shoppers used by stores.

Lastly, tertiary packaging generally comprises cardboard boxes used, for example, by the manufacturer to transport goods to the retailer, so as to group together a number of sales units or secondary packaging. Tertiary packaging can also be used as actual display stands for the goods, which is common practice in discount stores.

Depending on its composition, packaging can be:

- Mono-material, where it is made from a single material;

- Multi-material, where it features components made of different materials that can be separated by hand;

- Composite (also commonly known as laminate or polylaminate), where it is made up of two or more materials that cannot be separated by hand.

Reference standards

WASTE MANAGEMENT HIERARCHY 94/62/EC AND (EU) DIRECTIVE 2018/852

Directive 94/62/EC, amended by (EU) Directive 2018/852, is an EU regulation - implemented in Italy with D.Lgs 152/2006 and its amendments - that recognizes the fundamental social and economic function of packaging. The directive acknowledges that, where well designed, packaging provides proper storage and protection for the products it contains, ensuring that they do not become waste before reaching the consumer. More specifically, Directive 94/62/EC and its amendments maintains that packaging must be designed in such a way as to enable the recycling of at least a certain percentage by weight of the materials used, in compliance with current standards in the European Union. Said percentage may vary depending on the material in question and the targets to be reached in the near future.

(EU) Directive 2018/852 and its amendments must be applied to all packaging released onto the European market, as well as to all materials identified as packaging waste. It requires Member States to implement measures in order to prevent the generation of packaging waste - setting out an inverted pyramid with a descending order of preference for waste management procedures, Figure 2 - to encourage reduction of the environmental impact of packaging and to promote the creation of special deposit-return and/or collection schemes for used packaging and packaging waste within the various countries.

2005/270/EC DECISION

The 2005/270/EC Decision and its amendments establishes the formats relating to the database system pursuant to the packaging and packaging waste management hierarchy directive.

Indeed, it is up to each Member State to complete the above-mentioned reporting formats, which regard the recycling objectives defined in Directive 94/62/EC, reusable packaging, packaging waste, as well as traceability and assurance that waste is processed in an equivalent manner to the requirements laid down by the EU's environmental law.

The 2019 amendment (2019/665/EU Implementing Decision) implements the definition of composite packaging, allowing Member States to derogate from the requirements on reporting per material contained in the packaging, provided that it constitutes an insignificant part of the packaging unit (less than 5%). This means that when the reporting requirement provided for by the Decision comes into force, the relevant parties shall be required to report the amounts of different materials - even materials that are not predominant - placed on the market for consumption and sent for recycling where their percentage by weight is greater than 5%. This is different to the requirement until now, where the total mass of the composite packaging was reported under the one predominant material by weight.

97/129/EC DECISION

The 97/129/EC Decision determines the alphanumeric code describing the nature of the material(s) that make up a packaging unit, specifying which materials the identification system applies to.

The Directive concerns all packaging that falls under Directive 94/62/EC and, for paper, determines the abbreviation "PAP" followed by a relevant ID number that refers to the type of paper-based material used:

- PAP 20: corrugated fibreboard (grammage over 200 g/m2);

- PAP 21: non-corrugated fibreboard (grammage under 200 g/m2);

- PAP 22: paper

With reference to composite packaging, on the other hand, a material that is predominantly paper is identified with the abbreviation "C/PAP" along with a number that varies depending on the type of the non-paper material(s) used in the packaging.

ITALIAN DECREE (D.M.) OF 21 MARCH 1973

The Italian Decree (D.M.) of 21 March 1973 and its amendments establishes the composition and purity requirements for packaging due to be used in contact with food.

More specifically, it limits the filler content for packaging for which migration tests are required to a percentage equal to or less than 10%, which is increased to 25% for products where no migration testing is required. In addition, even water-soluble and partially water-soluble substances are regulated: the maximum permitted amount of soluble substances is 10%, while insoluble substances are accepted up to a maximum of 5%.

In addition, purity requirements put limits on the presence of substances such as lead and polychlorobiphenyls, as well as product categories for which optical whiteners can be used.

It should be noted that this Italian legislation allows the use of recovered fibres only for packaging in contact with dry foods, provided it meets the composition and purity requirements.

The Decree has been amended a number of times to comply with the requirements issued at a European level. In addition, despite it having been consolidated with the latest 31 May 2016 amendment with Decree n°142, there are types of materials not contemplated here that have instead been covered by other specific regulations.

STANDARD UNI EN 13430

Standard UNI EN 13430 and its amendments defines the requirements that packaging must meet in order to be recovered by recycling its component materials.

The standard sets out assessment criteria for parameters that help demonstrate the packaging's recoverability by recycling its materials, while also enabling the material recycling percentage to be determined.

The parameters tested regard all stages of the packaging's life cycle based on a Life Cycle Assessment (LCA) approach. More specifically, values are associated with each stage that correspond to recycling criteria, such as: control of packaging production and use, ease of recycling based on technologies currently available in the industrial arena, and substances released during the recycling process.

ATICELCA 501 AND ITALIAN STANDARD UNI 11743

The Aticelca 501 system was set up in 2011 as an instrument using a technical approach specifically geared towards paper-based packaging to define the requirements laid out in UNI EN 13430 and its amendments, as well as to encourage the uptake of eco-design practices among parties concerned with designing products made predominantly from paper, or parties who are involved in the development of new materials made predominantly from paper, or new additives.

It is worth pointing out that the Assessment system, followed by the Italian UNI standard, came about since they reflect and assess important aspects that find widespread practical application in Italy thanks to the plentiful infrastructure in the recycling chain for products made predominantly from paper. Aticelca 501 and UNI 11743 go over the industrial recycling stages on a laboratory scale, predicting what issues might be encountered during actual recycling in the paper mill.

With the Aticelca 501 system - which should be noted is a voluntary scheme - businesses that sign up can obtain permission to use the symbols indicating the level of recyclability (A+, A, B, C) - or, where applicable, unrecyclability - of the material or packaging as determined by testing.

Initially, the system included both criteria pertaining to experimental testing to be carried out on test samples, and assessment of the resulting parameters. Following the publication of standard UNI 11743 in 2019, relating to the experimental method of determining the recyclability parameters of materials and products made predominantly from paper, the Aticelca 501 system dropped its laboratory-based method, while retaining the assessment of results derived from tests as set out by the UNI 11743 standard.

More specifically, in order to achieve certification of the level of recyclability, the applicant must initially analyse the sample of the material or product as set out in standard UNI 11743 and then submit the results to Aticelca, who will assess them using the Aticelca 501:2019 assessment system, providing the applicant with the outcome and hence with permission - or not - to use the symbol and/or one of the marks attesting to recyclability in the paper mill.

STANDARD EN 643

The European standard EN 643 and its amendments is concerned with the standardization of products marketed in the European market, defining the various grades of paper and board for recycling and providing a description of the types of products that fall into the various classes of paper for recycling (commonly known as recycled feedstock). In addition, acknowledging the complex variety of materials found in the market, the standard introduces maximum tolerance levels for non-paper components, also providing a list of types of materials that should be regarded as unwanted or prohibited. With regard to the maximum amount of non-paper materials, the limit set for the majority of paper for recycling grades is 1.5% (the percentage refers to weight by weight).

Please note that the thresholds defined by standard EN 643 refer to the amount of foreign matter that may be present (for example, plastic bags, bits of glass, etc.) and do not refer to any of the paper product's constituents, even where they are non-paper constituents (for example, windows, adhesive tapes, staples, etc.).

Since this is a general reference standard for products made predominantly from paper, standard EN 643 regards paper and board items in general, including both packaging and products of other kinds. By way of example, it can include such materials as fluting for packaging, newspapers, magazines, labels and relevant liners, bags, cups and tableware.

The paper for recycling grade numbers defined are divided into five groups:

- Group 1 - Ordinary Grades: this is the group with the lowest-grade materials and hence with the least commercial value. It includes mixed unsorted paper and board, old corrugated containers, magazines, and paper for de-inking;

- Group 2 - Medium Grades: group 2 regards grade numbers for such recycled feedstock as unsold newspapers, heavily printed white shavings, and sorted office paper;

- Group 3 - High Grades: this group comprises white and mixed printer shavings, white newsprint, and white mechanical pulp-based paper containing coated paper;

- Group 4 - Kraft Grades: in the kraft grade group, we might find new shavings of corrugated board, grade 1 and 2 corrugated kraft, new kraft paper and board shavings, and used kraft paper and board;

- Group 5 - Special Grades: this is the group containing grade numbers relating to mixed packaging, paper-based composites for liquid packaging, laminates and coated kraft.

CE REGULATION 1935/2004

EC Regulation 1935/2004 establishes the characteristics that FCMs (Food Contact Materials and articles) must have and the common requirements they must meet, and complements EC Regulation 2023/2006 on good manufacturing practice. Both are of a general nature, and hence do not contain specific requirements.

They identify 17 classes of materials that may have specific measures in terms of requirements regarding purity or substances used, while also stating that packaging shall be accompanied by the words "for food contact" along with the relevant symbol. In addition, the Regulation allows for the use of active or intelligent food contact materials.

The principles set out in EC Regulation 1935/2004 are aimed at preventing packaging from endangering human health, bringing about a change in the composition of the food, or bringing about a deterioration in its contents.

Packaging made predominantly from paper

Definition of material and product made predominantly from paper

Before we launch into a description of the main types of packaging made predominantly from paper, we should quote the definition given in the Aticelca 501:2019 assessment system pertaining to materials and products made predominantly from paper:

Material made predominantly from paper: paper and board requiring additional processing to be converted into finished products (for example, rolls and sheets of paper for printing or making into boxes, sheets of fluting for producing packaging, reels of tissue for producing paper handkerchiefs). This material may contain other non-paper constituents not exceeding 50% by weight.

Product made predominantly from paper: finished article (such as packaging, printed material, household items) consisting of materials made predominantly from paper amounting to more than 50% by weight.

When it comes to packaging made predominantly from paper, this category can be split into:

- mono-material packaging, namely made from just paper;

- multi-material packaging, consisting of a main body made from paper, and components made from different materials that can be separated by hand;

- polylaminated or composite packaging, structurally composed of different materials that cannot be separated by hand.

Clearly then, the first definition given refers to a semi-finished product, the direct result of the paper mill's production process, while the second is an example referring to packaging made by producers. These products can also incorporate components that are not made predominantly from paper, such as plastic windows in bread bags, or rope handles on certain types of shoppers.

We should point out that the definitions adopted by Aticelca nonetheless refer to the concept of paper and paper products covered in standard EN 643.

SPECIFIC CHARACTERISTICS OF PAPER AND BOARD PACKAGING

Packaging made predominantly from paper varies hugely in type, shape and function and, depending on the nature of its contents, must ensure various mechanical or chemical and physical properties. Another significant aspect setting different types of packaging apart is the manufacturing process, which determines its technological parameters.

Properties and characteristics can be classed as follows:

- Chemica and physical properties

- Grammage

- Thickness

- Optical properties

- Permeability to gas or liquids

- Mechanical properties

- Tensile, compressive and bursting strength, tearing resistance, and folding endurance

- Impact absorption

- Stiffness

- Technological properties

- Surface finish

- Printability

- Formation

Generally speaking, paper is a material capable of readily absorbing moisture thanks to its inherent porosity and the hydrophilic properties of its component fibres. This absorption takes place regardless of the environment or contents, leading to deterioration in terms of both mechanical performance and physical properties. Consequently, water vapour barrier properties - as well as the ability to act as a barrier to other gases, such as oxygen, and other substances like lipids - are also relatively poor. While paper's breathability is often an advantageous property, in some cases - such as when it is required to package wet or greasy foods - it can be a hindrance. There are workarounds to this limitation that involve using barrier devices to avoid interaction with the outer in order to extend the product's shelf life.

In order to improve said properties, paper-based material can be laminated and coated with other materials that have different properties, such as plastic and aluminium: the choice is made at the design stage based on the specific application, and must take into account the nature of the contents and the properties to be provided that would otherwise prove critical using just a paper-based material.

Other types of coating may be called for to optimize the packaging's printing quality, especially when the inks due to be used are water based.

Paper, Paperboard, Corrugated Fibreboard

Since these terms are mentioned repeatedly herein, we think it would be helpful to provide a definition of each and go over the key aspects that set them apart.

The dictionary definition of paper is: "industrial product made from various fibrous substances (cellulose products, wood, straw, rags derived from plant fibres, etc.), which are mechanically and chemically treated to form a pulp from which - with the addition of additives, known as fillers, to give it special properties - thin, flexible sheets are made, used for various purposes." While this description touches on the raw materials and processes involved in the manufacture of paper-based products, there is no mention of the factor that differentiates paper, paperboard and cardboard.

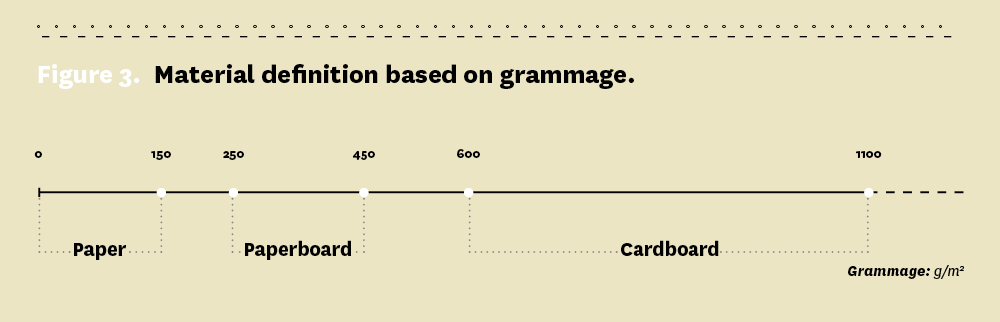

The property that defines a paper-based material is grammage (Figure 3), namely the weight per unit area. Paper proper has a grammage of up to 150 g/m2, while cardboard features a grammage in excess of 600 g/m2, and as high as 1100 g/m2. Paperboard, on the other hand, is a paper-based material with a grammage that lies between paper and cardboard, identified by a grammage in the 250 to 450 g/m2 range. If we look at the above figures, we can see that there are two apparently undefined ranges, namely between 150 and 250 g/m2, and between 450 and 600 g/m2: within these ranges, the line between paper and paperboard (in the case of the former range) and between paperboard and cardboard (in the case of the latter) is a little blurred.

Corrugated fibreboard comprises two sheets of rigid paper - known as linerboards - with one or more corrugated sheets - known as fluting paper - sandwiched between them: in the case of multiple flutings, these sheets are separated by an additional liner. The various layers are held together with usually water-soluble starch-based adhesives.

There are various parameters to consider and weigh up:

- The material used for the linerboards can range - across various different grades - from kraft (known for its excellent mechanical performance) to chip, which is made entirely from recovered fibres. Mechanical performance can vary depending on the type of virgin or recycled fibres used.

- Grammage ranges from around 150 g/m2 to around 450 g/m2, making a directly proportional contribution to the mechanical properties. Unfortunately, this also translates into increased weight for the finished product as the grammage goes up.

- The fluting can also be made from different grades of paper, with grammage generally ranging from around 110 g/m2 to around 210 g/m2. For the fluted media, another important parameter is the height of the fluting, which can be used to produce total thicknesses of between 1.5 and 15 mm. Different flute profiles are identified with different alphabetical letters.

Generally speaking, higher flutes result in greater edge crush strength - forces in the same plane as the sheet - compared to lower flutes, while they give poorer flat crush strength - forces at a right angle to the surface of the sheet. In addition, printing on higher fluting is more difficult as the distance between flutes increases and, consequently, the linerboard is not perfectly flat. Lastly, while greater corrugated fibreboard thicknesses result in greater resistance to the impact of external objects during transport, for example, they also increase the overall space taken up by the item during transport.

Materials used for packaging

Now that we have defined what we mean by materials made predominantly from paper and described the various types of paper based on their grammage, we will go on to describe the different materials used in packaging made predominantly from paper and board. These materials are identified, first, based on whether they are mono-material or composite in nature and, then (for mono-material materials) based on their grammage.

Consequently, the following types of materials are identified below:

- Paper

- Rigid paperboard

- Cardboard

- Corrugated fibreboard

- Composites

- Special papers

- Cellulose pulp

Since the above-mentioned types of materials have different properties that serve different packaging functions, it naturally follows that different types of packaging will be suited to different uses.

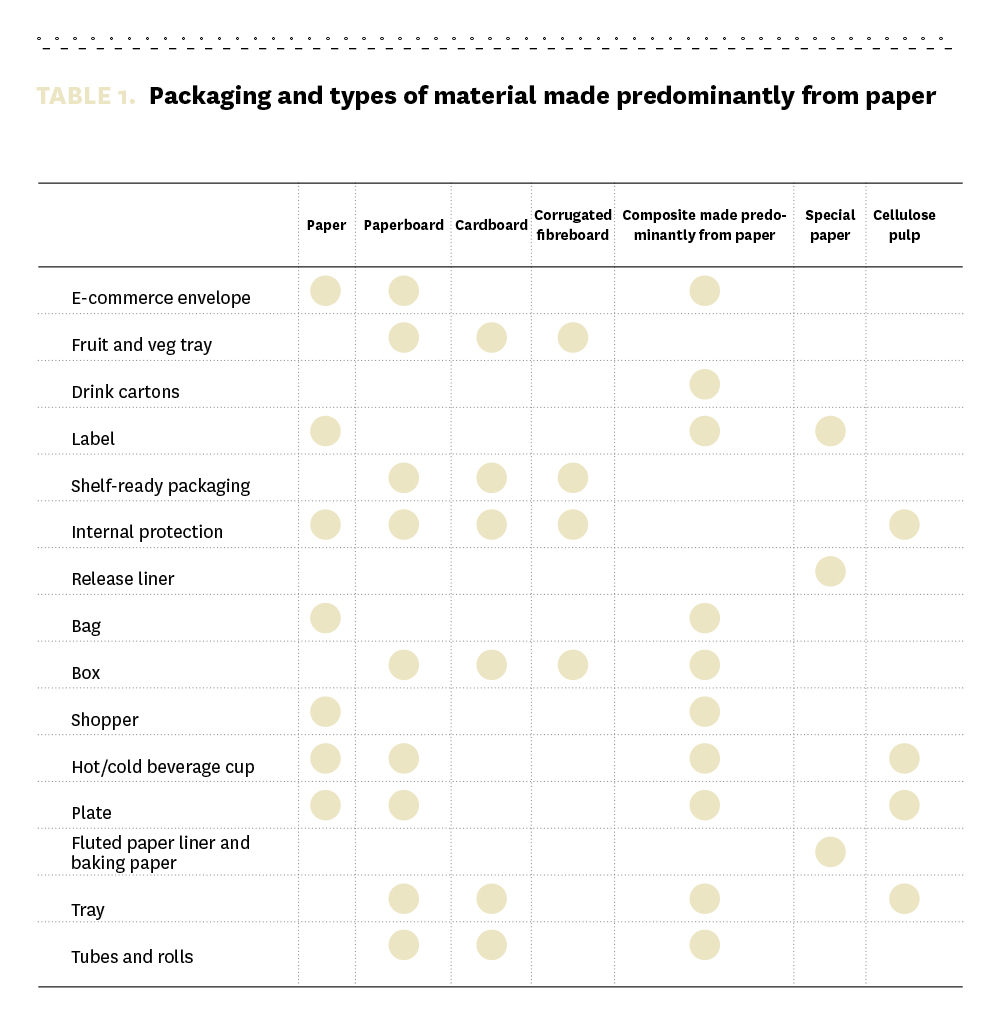

Below (Table 1) is a table summarizing the most common predominantly paper-based material/packaging combinations. Clearly, we should also point out that the various types of packaging featured in Table 1 in no way represent the full complement of packaging placed on the market for consumption.

PAPER

Paper, by its very definition, is generally very thin, which gives the packaging breathability, but poor mechanical performance in terms of tearing and puncture resistance, while resulting in an exceptionally flexible and light end product. Of course, this performance can be adjusted based on the average length of the fibre, as well as the thickness of the sheet of paper used.

Packaging made from paper is generally mono-material, though it may incorporate components made from other materials, such as plastic windows (take, for example, those found on bread bags), making the packaging more functional, in this case by making the contents visible. The downside of mono-material solutions is poor mechanical strength in the event the packaging becomes damp or wet.

Paper-based packaging comes in different sizes and types, the main ones being bags (for fresh products, such as baked goods or fruit and vegetable produce) and sacks (for semi-finished industrial products, by way of example), through to shoppers, self-adhesive labels, and internal protection (paper void fill, linings and paper cushioning).

Long fibres are usually employed in the case of paper bags, sacks and shoppers, offering mechanical strength (kraft paper), while recycled material is generally used for paper fill, with grammage in the 50 a 70 g/m2 range.

PAPERBOARD

Rigid paperboard is thicker than paper, and can withstand greater mechanical stress, while flexibility is more limited.

These inherent properties make it ideal for making products that are self-supporting when moderate compressive loads are applied, such as in the case of units of the same product being stacked on top of each other several units high. Packaging made from rigid paperboard is mostly mono-material, while it may incorporate the occasional non-paper accessory, such as plastic windows.

Packaging products made from paperboard come in many shapes: light cartons (for dry foods, with or without the addition of accessories not made predominantly from paper), boxes (for example, for the pharmaceutical industry, for industrial products or cosmetics), mono-material envelopes for e-commerce (with adhesive strip closures), internal protection such as corner protectors (a number of sheets of paperboard can be bonded together to increase the item's thickness and mechanical strength) and, lastly, reels, rolls, tubes and cylinders (for food products, or for winding flexible material on that is not for domestic use only), and trays (which may or may not be laminated with a layer of plastic).

CARDBOARD

Out of paper, paperboard and cardboard, cardboard is the material with the best mechanical performance, though this is at the expense of thickness and flexibility. In addition, structural performance increases at the expense of the finished product's lightness.

Like with paper and paperboard, one of the most popular solutions - which also proves the best for recycling processes - is the production of mono-material packaging.

Cardboard applications features types of products that are very similar to paperboard packaging, namely: cartons and boxes (for example, for transporting fragile items), internal protection, such as corner protectors and, lastly, reels, rolls, tubes and cylinders (for winding flexible material on that is not for domestic use only).

CORRUGATED FIBREBOARD

Corrugated fibreboard stands out for the sheer variety of applications it can be used in. Indeed, there is ample scope for fine-tuning during the semi-finished product's manufacturing process. The various options - such as the type of paper used - include the number of flutes and their height, inherently determining the end thickness and mechanical properties: puncture resistance, printability, stiffness, etc. It is usually sold in sheets, though it can be found wound on reels where it features a single flute and single face.

Packaging made from corrugated fibreboard is generally light and self-supporting, while it is also frequently bulky. Corrugated fibreboard packaging is generally designed to be stacked and withstand the often considerable weight of both the stacked units and their contents.

The main types of packaging made from corrugated fibreboard are trays (usually meant for fruit and vegetable produce), cartons and packing boxes (secondary/tertiary packaging designed both for storage and logistical purposes within the distribution chain, and for e-commerce), shelf-ready packaging (serving the dual purpose of protection and containment during the product's distribution, and then used to display the product on the store shelf, fulfilling its communicative role), and internal protection items (layer pads, dividers and fitments in general).

COMPOSITE PACKAGING MADE PREDOMINANTLY FROM PAPER

To enable paper-based packaging to be able to cope with liquids, and to improve its gas barrier properties, the paper component is sometimes laminated with other plastic or metal materials. Composite packaging is particularly useful for holding goods that require specific internal atmospheric conditions for their correct storage, whether they be solid foodstuffs - such as biscuits, cold meats or chips - or liquids, like hot beverages or fizzy drinks (take, for example, hot or cold beverage cups).

The lamination is specially designed to give the packaging improved barrier properties, especially in the case of food-grade packaging, which is required to meet statutory purity and composition requirements. The downside, though, is that these properties have a negative effect on the ease of post-consumer packaging recycling.

The paper stock can be laminated on one or both sides with one or more layers of plastic (usually polyethylene - PE, polypropylene - PP, or polylactic acid - PLA), or with plastic layers plus a layer of aluminium, as well as with layers of metallized plastics. Since every application requires different performance, it follows that the number of layers to be placed on top, and the material used for each of these layers, needs to be determined on a case-by-case basis.

Some examples of composite packaging include drinks cartons (packaging for goods such as juices, milk, wine, etc.), sacks and bags (for biscuits, cold meats and industrial material), disposable tableware (plates, cups, and trays), tubes (for products such as crisps), as well as labels and padded envelopes for e-commerce (envelopes lined with bubble wrap and with a waterproof outer layer).

SPECIAL PAPERS

Special papers comprise a layer made predominantly from paper to which other substances and/or materials are applied, either inside the material in question or as a coating, to boost the properties of the substrate.

More specifically, the common types are:

- Silicon-coated paper: during production of this kind of paper, a small percentage of silicone (usually around 3%) is added, enabling the packaging to withstand temperatures of around 200 °C, while also giving it non-stick properties - ideal for cooking food;

- Wax papers: papers coated with wax, often on both sides. Wax gives the packaging water- and oil-repellent qualities, while also increasing its water vapour barrier property. Ideal both for food products and for use in engineering, which involves handling often greased or lubricated parts and products;

- Tar papers: papers coated with a layer of tar, making it waterproof. They are usually used as a lining inside wooden crates for shipping over water.

This type of packaging material is generally sold in the shape of sheets or rolls, or wound on reels, and has issues when it comes to recycling due to the use of materials not made predominantly from paper. In the specific case of silicone-coated paper, it also comes preformed (fluted paper liners) for baking food, as well as in the shape of release liner rolls for self-adhesive labels, which have to be able to withstand the considerable mechanical stress of being put through the labelling machine.

CELLULOSE PULP

Cellulose pulp is the raw material used to produce sheets of paper and is a plant-derived material obtained from logs or chips, by-products of timber processing. In order to obtain an optically white product, the pulp is chemically treated with oxygen and catalysts.

Since cellulose is hydrophilic in nature, cellulose pulp can be waterproofed by coating it with plastic films that can be obtained from renewable or non-renewable sources without distinction, and may be biodegradable and compostable.

Cellulose pulp can also be used to produce paper-based products not made from a sheet, instead pressed or thermoformed directly from the cellulose pulp. The resulting cellulose pulp packaging is usually heat resistant (temperatures up to 200 °C), which means it is commonly used for the food industry.

In addition, because it comes in bale form as opposed to sheets or reels, the end packaging's production processes are basically different from the cutting, folding and gluing processes usually adopted for other paper-based semi-finished items. In this regard, technologies such as moulding and thermoforming make cellulose pulp packaging morphologically more complex than the other types mentioned thus far.

The pulp is used to make boxes (for products such as eggs), inserts (by way of example, used in the electronics industry for packing TVs, laptops and shavers), as well as disposable tableware (such as plates, takeaway trays, bowls, and hot and cold beverage cups).

Boxes in e-commerce

E-commerce is a method of buying and selling goods or services spawned by the development of the internet and online shopping giants. The estimated value of this market worldwide is said to be in the thousands of billions of euros, with a strong growth trend both in Italy and across the globe.

Over the years, the increase in e-commerce has led to greater market globalization, thus affecting the population's shopping habits.

Recently, the percentage growth in digital sales volumes has shone the spotlight on the opportunities presented by this market, as well as its restrictions and difficulties. In this regard, Comieco, in collaboration with Netcomm, have published guidelines for the correct use of packaging in e-commerce.

Products sold through e-commerce channels are shipped inside packaging such as cartons and packing boxes, padded envelopes and bags made from plastic. The packaging most commonly used to ship goods consists in cartons and packing boxes made from corrugated fibreboard. This kind of packaging is produced in different sizes, chosen based on the size of the item it is due to hold. The package to be shipped is generally bulky and needs suitable inserts or fill to protect the goods being transported inside the box.

The various aspects to be taken into consideration, in addition to the glue used to fasten the box's flaps, include the possible use of staples and, above all, adhesive tapes, which are often not paper based (the latter in generous amounts) and, in some cases, the use of plastic transport document wallets. These components can negate the paper mill recycling process - albeit in different ways - as they are not composed of cellulose fibres, thus generating waste to be sent for other forms of recovery.

The collection, sorting and recycling process for packaging made predominantly from paper

Introduction to the recycling chain

Designing means conceiving the end product with an all-encompassing approach. This means design does not stop at working out the details of the shape and function of the packaging, how it is used, how it communicates with the user, or how to make it compliant, it also means being familiar with the whole product life cycle. More specifically, it means being aware of what happens once a product has served its purpose and must be handled and recycled in order to produce new material.

When it comes to packaging - in this case packaging made predominantly from paper - being familiar with the recycling processes is also key in designing packaging that is going to be compatible with said processes. Furthermore, given that Italy is a resource-poor country and hence is dependent on imports to meet its virgin fibre needs, it proves to be in the interests of the whole paper industry - and advantageous for the country's balance of trade - to try and recover as much fibre as possible to be reintroduced into new products by means of recycling processes.

When it comes to design for recycling, it is important for designers to be familiar with and take into consideration the packaging's various end-of-life processes. That way, designers can come up with alternative solutions geared towards the generation of best practices aimed at optimizing the recycling of paper and board packaging products.

The aim of this section of the document is to provide a basic yet exhaustive description of the activities making up the recycling chain for materials made predominantly from paper, dividing them into three main processes:

- Collection

- Sorting

- Recycling

THE SUPPLY CHAIN IN ITALY AND EUROPE

Paper and board product collection, sorting and recycling are processes that serve to extend the service life of cellulose fibres. These fibres can actually be recycled up to seven times on average before they become too short to be reused.

The material entering the recycling process can come from two different streams:

- From the collection of municipal waste handled by local authorities, which includes all post-consumer products;

- From the collection of industrial streams, made up of industrial packaging and waste.

While municipal waste collected from households regards a diverse assortment of products made from different types of predominantly paper-based materials that require sorting before they can actually be recycled, the industrial waste streams collected comprise a well-defined and coded homogeneous stream of industrial by-products and packaging waste, allowing paper mills to use it without any intermediate steps.

Recycling products that have reached their end of life is essential as, on the one hand, it delivers environmental benefits and, on the other, socioeconomic benefits for the community. These include:

- Direct and indirect benefits for the national economy;

- Generated secondary raw material;

- Energy savings;

- Reduction in carbon dioxide (CO2) emissions.

The direct benefits are closely linked to the economic value of everything that is collected and recovered via the recycling process, and the heat energy or electricity produced with energy recovery processes, while indirect benefits refer to the reduction in pollutants.

In terms of secondary raw material generation, the benefits lie in the recovery of packaging waste and the reduction in the amount of virgin material that needs to be sourced. When we refer to energy savings, on the other hand, we mean the electricity and heat energy produced by waste-to-energy plants. The recycling process results in a reduction in the amount of CO2 - one of the gases deemed responsible for the greenhouse effect - emitted compared to that involved in production using virgin material. Similarly, electricity or heat generation via waste-to-energy processes (energy recovery) produces less carbon dioxide than processes that involve the use of fossil-based material.

Another aspect worth taking into account as part of a broader assessment is that, with the cellulose used being sourced from sustainably managed forests, the plants harvested are continuously replaced with new plants that generate CO2 absorption as they grow.

In Italy's paper industry, the use of fibres derived from recycling accounts for more than half (at least 55%). If we also take into account - again taking just the case of Italy - the fact that there is a limited amount of virgin fibre produced domestically, and that this material, therefore, mostly has to be imported from abroad, it comes as no surprise to learn that the country has become one of the top performers in Europe in terms of the collected and recycled fraction, and has already exceeded the target set by (EU) Directive 2018/852 for 2025.

Across Europe, too, paper and board are the materials with the highest recycling rates, and these rates go up even further if we take just packaging made predominantly from paper.

Recycling drinks cartons

Paper-based composite packaging requires specific conditions for recycling as it is made from different materials that cannot be separated from each other by hand. Paper mills manage to recover cellulose fibres by separating them from other materials.

Recycling this packaging is very important as the cellulose content is highly valued, being made up of long fibres that can be processed and recycled time and time again before they lose the minimum structural properties required to generate pulp and be reused in new products.

Consequently, this type of material constitutes a source of secondary raw material to be exploited to the full. In this regard, there are currently two paper mills in the Italian arena capable of processing and recycling composite packaging made predominantly from paper designed to contain liquids: mostly the aforementioned drinks cartons. These two mills alone, in 2018, managed to process about a fifth of the total amount of drinks carton packaging sent for recycling, while also announcing that they plan to double this amount by strengthening the link between the various players in the recycling chain handling products made predominantly from paper.

Compostability in Italy

Recent studies have shown how giving packaging barrier properties against liquids, lipids and gases, or against the possible migration of contaminants, has led to an increase in the market share relating to biocomposite multi-material packaging made predominantly from paper, although it still accounts for only a very small percentage of the total volume of packaging made predominantly from paper.

The packaging in question comprises a paper-based material laminated with bioplastics. With the use of these materials, paper can be enhanced with new functions, without interfering with its inherent properties as a biodegradable organic material. The use of these materials means that paper packaging that is contaminated or has organic residue on it that would usually preclude its recovery through recycling, can instead still be recovered within the organic waste supply chain.

On the subject of bioplastics, we should specify that the term includes several families of materials featuring different properties:

-

Biobased: a material derived at least in part from biomass; examples of plants from which biobased materials can be obtained include maize, sugarcane and hemp;

-

Biodegradable: biodegradability is the property of a material to be converted to simple substances such as water and carbon dioxide by means of a chemical process, through the action of microorganisms, within set time limits.

Please note that the two properties mentioned above are mutually independent as there are materials derived from biomass that are not biodegradable (e.g. Polyethylene Terephthalate obtained from renewable sources, bio-PET), and petrochemical-derived materials that are biodegradable (e.g. Polycaprolactone, PCL).

We should also underline the difference between compostable and biodegradable: while all compostable material is biodegradable, not all biodegradable material is compostable. This is because compostable materials become biomass, while the same is not necessarily true of biodegradable materials. Standard EN 13432, for example, specifies that a material, in order to qualify as compostable, must:

-

Break down into carbon dioxide by at least 90% within six months (to be tested as set out in standard ISO 14855)

-

Disintegrate into small fragments measuring less than 2 mm when placed in contact with organic materials for three months (to be tested as set out in standard ISO 14045)

-

Not have negative effects on the composting process

-

Demonstrate low concentration of heavy metals added to the material

-

Demonstrate pH, nitrogen and phosphorus values, and amounts of other substances, within the set limits.

These factors are key when it comes to designing packaging, as the choice of material inevitably affects the end product's end-of-life options. While the packaging's predominantly paper-based materials make recycling the preferred option, compostability - subject to certification to current standards - is a viable alternative, specifically for packaging made from paper in direct contact with moist or greasy food, given the existence of industrial aerobic composting plants capable of suitably handling this kind of packaging's end of life, at least as long as the waste percentages entering the organic waste stream are on a par with today's values.

When considering this kind of packaging's end-of-life destination, it is worth bearing in mind these two points:

-

Any bioplastic layers are processed in paper mills as traditional plastic and, as such, contribute to the production of pulper rejects usually sent for energy recovery, meaning they are treated no differently to a traditional paper/plastic laminate;

-

Where the application in question concerns disposable food packaging - which has stricter recyclability limits linked to contamination with food residue - the paper/bioplastic lamination makes it potentially suitable for organic waste collection and recyclable via the organic waste process. To this end, though, it is always best to verify the actual biodegradability and compostability of the whole finished packaging as set out in standard UNI EN 13432.

Collection

SEPARATE COLLECTION OF POST-CONSUMER PACKAGING

Separate municipal waste collection - which includes the collection of packaging made predominantly from paper - is organized and handled by the local authorities, who determine the relevant procedures, which therefore vary across the country from area to area. The consumer plays a crucial role in source separation and hence in ensuring packaging waste is sent for recycling.

It is worth remembering, then, that the packaging's design can be a significant aid to local authorities by promoting source separation, helping users perform their waste separation duties, disposing of packaging into the correct recycling stream.

We should also point out that packaging made predominantly from paper and similar fractions make up the second largest separated waste fraction in terms of the quantities collected nationally - amounting to almost 3 and a half million tonnes in 2018 - beaten only by the organic fraction (organic household waste and green waste). The data for this fraction show an uptrend over the years, with values having more than doubled compared to values pre-dating the new millennium.

COLLECTION OF PACKAGING FROM THE INDUSTRIAL SECTOR

Unlike municipal waste collection, material collected from the industrial sector can come from businesses, from supermarkets and retail chains, from the newspaper industry, from box factories, or from any company in the industrial or service sector where packaging made predominantly from paper is used in at least one of their operations.

Used packaging is collected and taken to sorting facilities - who handle the next stage - through a dedicated channel that involves the use of containers, compactors or - especially for supermarkets and retail chains - the use of bales tied with metal or plastic straps.

Part of these streams may then be introduced into the municipal waste stream as a result of the local authorities' decision to combine commercial and municipal waste. These are typically streams from small and craft businesses.

Shavings and, in general, rejected material and scrap generated by paper-transformation and printing processes are another matter. In this case, since the discarded materials in question come from an industrial process without being its primary purpose, they do not require any sorting and thus qualify as by-products. These materials are not regarded in any way as waste and are typically sold directly to paper mills (the same mill that supplied the paper is often the one to collect the shavings and recycle them) or sold through brokers.

Sorting

Given the different nature of municipal streams compared to commercial and industrial streams, they are processed separately. Material intercepted in commercial and industrial streams, for example (scrap, products not released onto the market, packaging from supermarkets and retail chains, etc.), proves more homogeneous. Consequently, these streams can generally be assigned recycling grade numbers associated with higher grades than those assigned to material coming from the source-separated municipal waste stream.

Below is a diagram and relevant description of an advanced sorting process: the term advanced is used as it also employs automated sorting technologies.

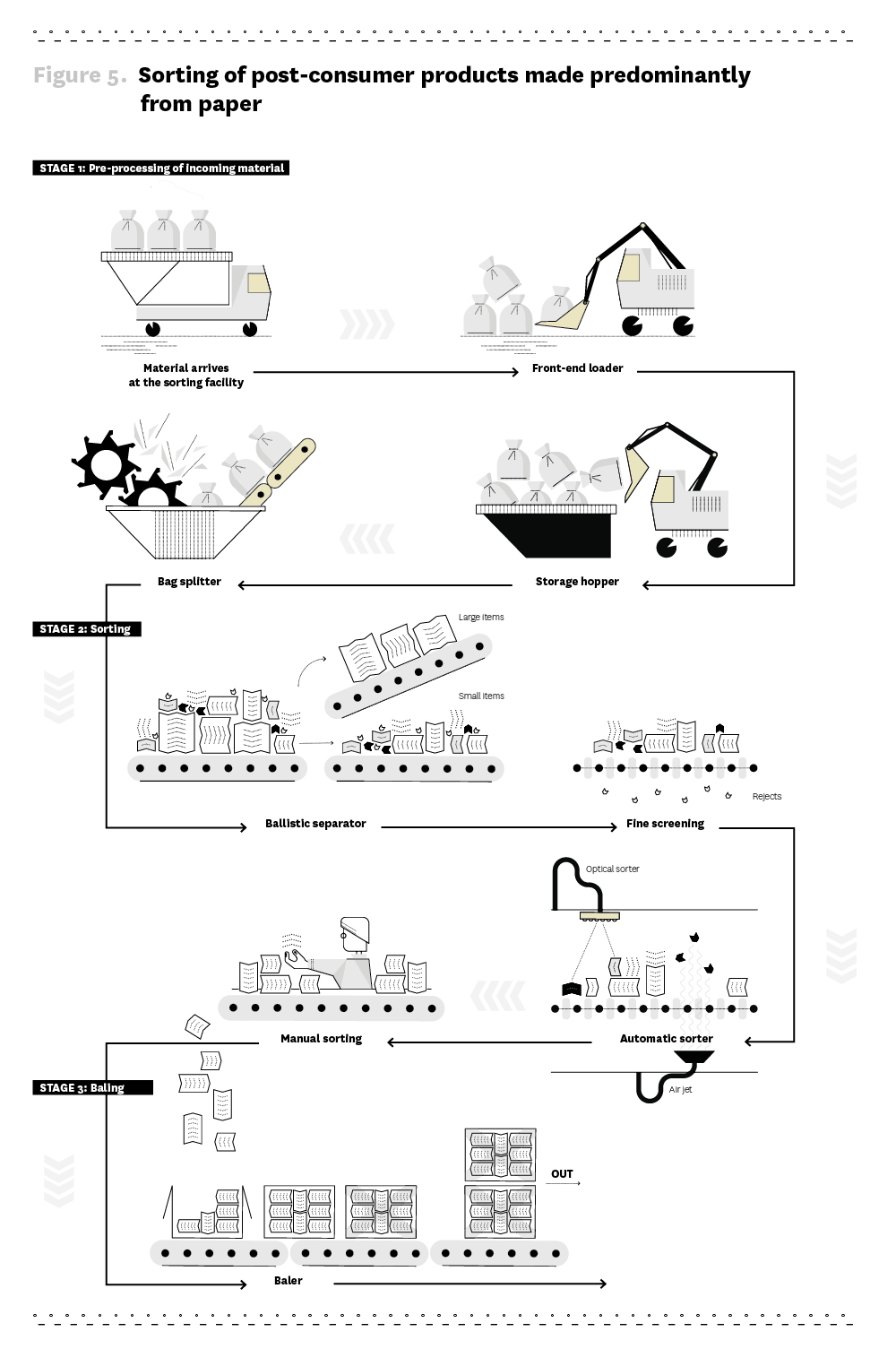

SORTING OF POST-CONSUMER PRODUCTS MADE PREDOMINANTLY FROM PAPER

STAGE 1: Pre-processing of incoming material

- The material coming in from municipal waste collection is brought to the facility and off-loaded onto the plant's tipping floor. An operator uses machinery to handle the above-mentioned material, transferring it to a storage hopper.

- The material is carried on a conveyor belt from the storage hopper into a special piece of equipment that automatically opens any bags (plastic or otherwise) used for collection. This step allows the subsequent stages to reduce the amount of rejects to be sent for other forms of recovery.

STAGE 2: Sorting

- The material continues its journey through a ballistic separator that uses reciprocating motion to pre-sort the material based on the size of the pieces of paper and board. More specifically, the material that does not fall through the openings - namely, the larger items, referred to as overs, usually ranging from 20 to 30 cm in diameter - is generally corrugated fibreboard. This means best practice is to ask consumers not to break corrugated fibreboard products up into small parts, thus reducing the amount that gets through the ballistic separator's openings.

- Everything that counts as medium to small in size continues its journey along a conveyor belt for a fine-screening process, whereby any small items - which are usually not made predominantly from paper - are separated.

- Next comes an optical sorter via which the material can be sorted into specific colours - or plastic (if any) separated out - by means of an air jet that sends it to a specific form of recycling (in the case of coloured/white paper and paperboard), or disposal/recovery (in the case of other materials).

- Lastly, manual sorting removes any foreign matter that has not yet been rejected, ensuring that the resulting material meets the quality requirements set by the paper mill. In addition, operators can separate specific paper for recycling grades based on market demands.

STAGE 3: Bailing

- The last stage entails baling the processed material to produce a sales unit that is easy for machinery to handle and for transporting to the paper mills.

Consequently, a conveyor belt carries the material into a baler that presses it and binds it with metal straps. The resulting product thus comes in the shape of a unit roughly one metre in size (although length can vary depending on the sorting facility) and weighing around 1200 kg. - Once the process is complete, the bale is stored until it is sold to a paper mill.

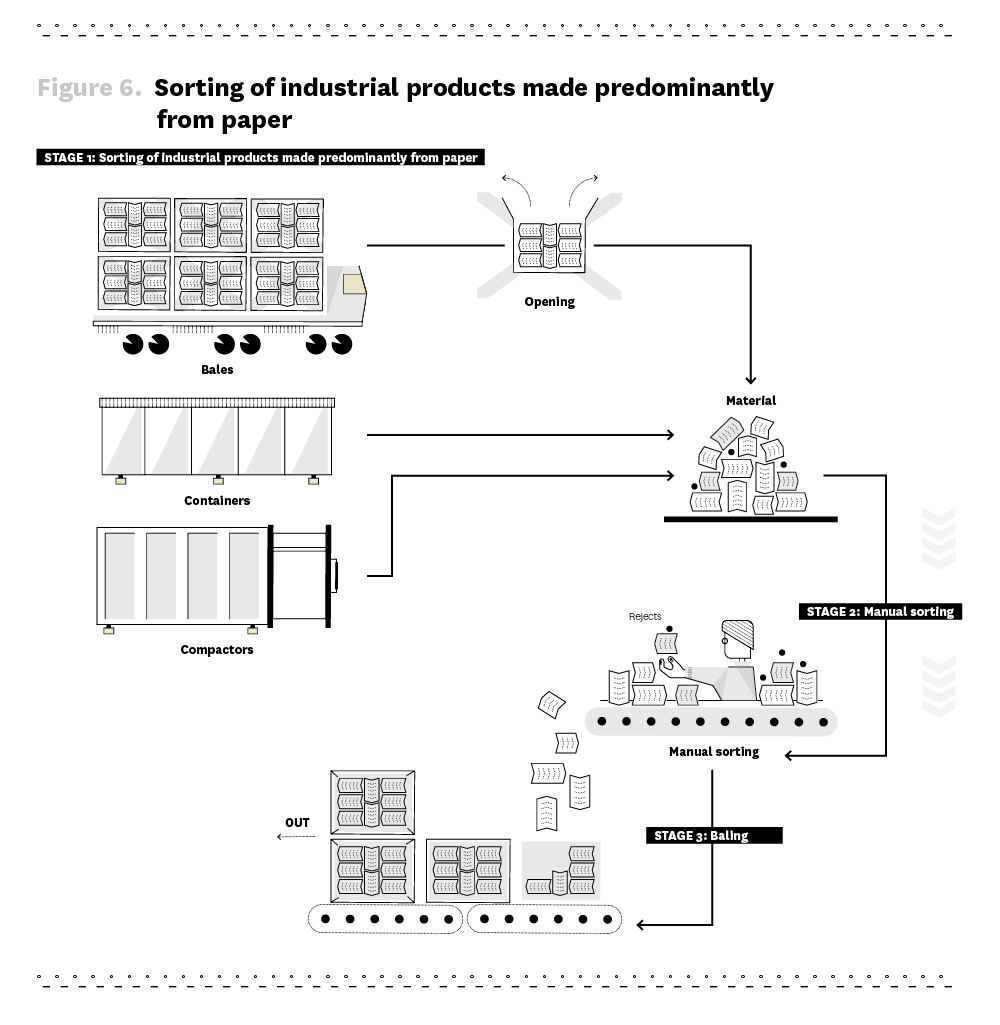

SORTING OF INDUSTRIAL PRODUCTS MADE PREDOMINANTLY FROM PAPER

STAGe 1: Manual sorting of incoming material

- Any bales of material collected from the commerce and industry circuit are opened. This typically occurs when the stream comes from supermarkets and retail chains and from businesses in general. Otherwise, the material is moved straight onto the next stage.

STAGE 2: Manual sorting

- Operators remove by hand any products spoiling the lot, ensuring that the material meets the standards of quality demanded by the paper mill.

STAGE 3: Bailing

- A conveyor belt carries the material into a baler that presses it and binds it with metal straps. The resulting product thus comes in the shape of a unit roughly one metre in size (although length can vary depending on the sorting facility) and weighing around 1200 kg.

- Once the process is complete, the bale is stored until it is sold to a paper mill

Paper mill recycling process

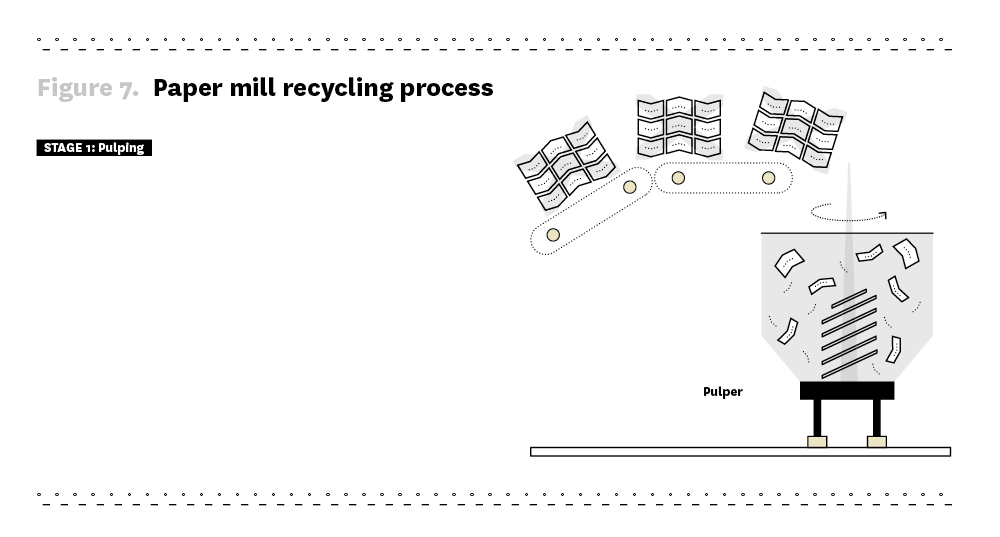

STAGE 1: Recipe formulation and pulping

- The recycling process starts with formulating the recipe for the slurry to be processed and loading the required quantities onto the conveyor belt. The material is loaded in bale form, as it arrives from the sorting facilities. The recipe is a mixture of different types of pulp.

- The amounts loaded onto the conveyor belt are introduced into the pulper, which then separates the fibres. This is generally a mechanical process (involving a rotor located on the bottom of the equipment), and may be aided with chemical treatment. Nowadays, this recycling process is seeing a growing amount of packaging and products made from recycled paper. So, to avoid the fibres breaking too much, the fibre processing time and relevant temperatures are being reduced. Consequently, with the option of recycling more complex materials, such as paper-based composites, the process itself is also becoming increasingly complex, hence:

- Longer retention times are required to process stronger materials, such as fruit and vegetable produce trays;

- Shorter retention times prove better suited to less structured products, such as sheets of paper or shoppers that would otherwise have their fibres broken down, shortening them too much and hence resulting in poorer quality.

A pulper generally works at low temperatures, staying under 40 °C.

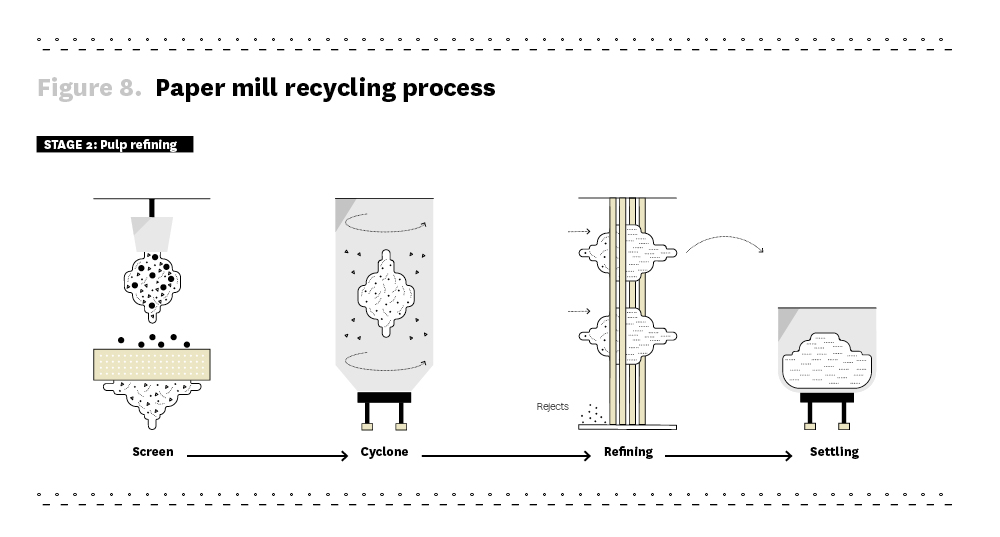

STAGE 2: Pulp refining

- Once slushed, the pulp is sent through a screen made up of holes measuring approx. 14 mm in diameter. The purpose is to eliminate any contaminants in the bales introduced into the pulper.

Another fraction of material that is rejected by this initial screening process is made up of all those products that can be only partially pulped, or have not been pulped at all, and this can include products laminated on both sides, composites and adhesive tapes.

- Anything that does not make it through the screen is transferred to a concrete mixer, inside which it is rinsed and then collected and treated by the paper mill as waste.

- The water-based mix (approx. 95% of which is water) that instead makes it through the screen is then sent to a series of cyclones (cleaners). Here, any small foreign matter - such as bits of broken glass, metal fragments, etc. - that would interfere with the papermaking process is separated by gravity.

- Rejected material is collected and then treated as waste.

- The material that makes it through this stage is processed in a number of steps through a basket with smaller and smaller slots for more thorough screening of the pulp.

- Rejected material is collected and then treated as waste.

- These steps are also effective in separating out any non-soluble adhesives and glues to stop them ending up in the paper at the end of the new sheet forming process. These materials are handled like the other kinds of rejects

- At this point, in some cases, a refiner is used that - with bars set approximately 0.1 mm apart - expands the fibres, resulting in a reduction in the porosity and elasticity of the paper that will be produced with said material, and thus enhancing its mechanical properties.

- The fibre suspension is transferred to the mixing chest, where specific substances are added to it, such as:

- Optical bleaching agent

- Bactericide

- Fillers (kaolin and calcium carbonate dispersion in water) to increase opacity and smoothness

- Cationic starch solution to bind the paper pulp's anionic fibres

- Glue (sodium resinate), this is a pine extract used to enable the ink to set on the paper

- Cationic polyacrylamides, as coagulants

- Lastly, the slurry is conveyed into an area where it is allowed to settle and blend; this process levels out consistency and allows the fibres to absorb the water.

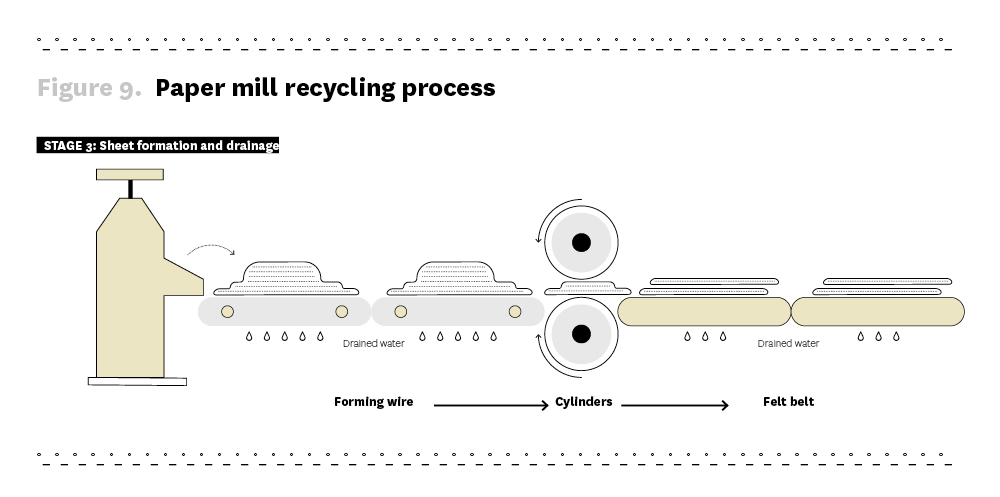

STAGE 3: SHEET FORMATION AND DRAINAGE

- At the end of the pulp preparation area, the paper sheet forming process proper starts: a (99%) water-based fibre slurry is placed on the flat deck (also known as the forming wire) inside the headbox. In this machine, the slurry is distributed perfectly uniformly and evenly across the wire, trying to avoid imperfections of any kind due to foaming or the formation of eddies.

- The wire - which travels at speeds as high as 100 km/h in some cases - allows the slurry to drain, thus progressively losing most of the water it contains and encouraging the cellulose fibres to mesh together, since at the forming stage, the sheet still does not have its final consistency or mechanical properties.

- To remove additional water, the sheet is fed through pairs of counter-rotating cylinders where it is pressed, through suction boxes and through wet-end presses.

- The sheet of paper leaves the wire and is switched to a felt belt, which absorbs further water, leaving the sheet with approx. 45% solids.

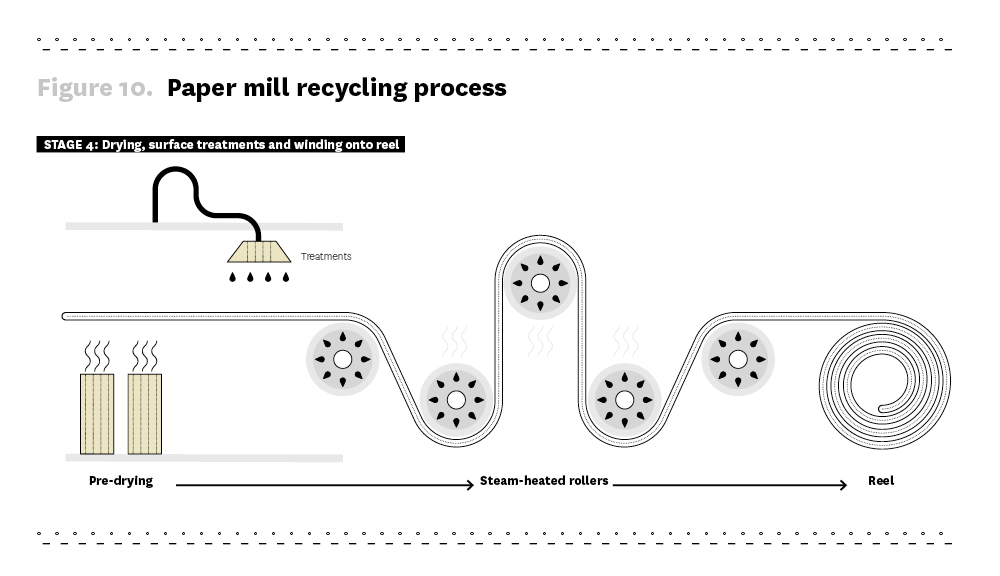

STAGE 4: Drying, surface treatments and winding onto reel

- The material is then processed in the pre-dryer, where the moisture content is reduced.

- This allows the sheet to be treated, at a later stage, with a water-based starch solution (potato/maize flour, etc.), optical bleaching agents and surface sizing agents.

- To eliminate any remaining excess moisture - added during the last treatment - and leave approx. 5-6% solids (where the finished product finds its balance), the sheet of paper is fed through the dryer, which consists in a series of rolls through which high-pressure steam is sent at a temperature in excess of 100 °C.

- In order to increase surface accuracy and relevant finish, the sheet can be calendered: through the mechanical action of rolls, the surface of the paper is smoothed and hence made extra glossy.

- For increased printability, the sheet can be coated, by applying substances to the surface of the sheet such as calcium carbonate, kaolin and gypsum, held together by a binder, resulting in a uniform, dense surface capable of absorbing ink evenly.

- The last step is winding the paper onto reels and, where necessary, re-reeling to split the roll into smaller rolls.

Notes on pulper rejects and on treatment water

Pulper rejects are one of the main kinds of waste generated by the paper recycling sector. Pulper rejects are inevitable and are made up of non-paper or non-pulpable materials found in the recycled feedstock that cannot be recycled in paper mills. They are separated from the pulp by means of one or more actions:

- Force of gravity;

- Centrifugal force;

- Uso di screens.

Despite new solutions being tried out, pulper rejects are destined for landfill or for energy recovery in special waste-to-energy plants.

While rejects account for only a minority fraction of the total amount of material introduced into the pulper, the ensuing effects can be considerable: for example, if the non-paper fraction in the pulper holds on to the fibres, not allowing them to detach, then the whole pulp might have to be rejected.

As already pointed out, recycling is a water-based process. Despite the fact that technological progress has led to significant savings in terms of the consumption of this raw material - with a process water recycling rate that can top 90% - there are still steps in the recycling process that require substantial amounts of water per unit of paper produced. Consequently, managing its treatment before it is reused or discharged into surface water is a hugely important part of the process.

Post-process water is conveyed into a tank where the fibre fraction is recovered by means of a semi-flotation process: air bubble generators inside the tank allow lighter fibres to be carried to the surface, where an instrument scoops them up. A similar process takes place on the bottom of the tank, where the heavier fibres are recovered.

The water then goes through a sequence of aerobic treatment steps, possibly followed by an anaerobic stage, and settling. After this, the water can be discharged or reintroduced into the papermaking cycle, depending on the paper mill's needs. Treatment sludge thus constitutes a typical sort of waste, although in some cases it can be reused in the papermaking process.

While pulper rejects are mainly destined for energy recovery, rather than being landfilled, paper mill sludge can also be used for environmental rehabilitation projects or employed in other sectors, such as the concrete and brick industry. In some cases, the fibres it contains may even be downgraded, hence the sludge produced by certain paper mills may be used by other paper mills.

Design guidelines for facilitating the recycling of packaging made predominantly from paper

General design principles to facilitate recycling

When it comes to paper and board products and, more specifically, packaging made predominantly from paper, the first thing to consider is that - despite this material having anything up to 7 "lives", each time becoming part of a new product as part of a closed process (from paper mill to paper mill) - the average "life" of the fibre in Europe comes in at 3.6, while globally this value drops to 2.4. Consequently, it is imperative that every effort be made to exploit the material used, keeping the cellulose fibres in the supply chain for as long as possible before they are finally disposed of for good.

In the coming sections, we will be setting out design guidelines that facilitate the recovery of cellulose fibres in end-of-life packaging, in order to foster greater circularity in the industry. There are actually various factors that affect the recyclability of packaging made predominantly from paper, from correct waste separation by consumers through to sorting and recycling processes, with possible technological or technical limitations.

As a general rule, for example, opting to use recycled material, where possible, is almost always a good option. This then becomes an outlet for the feedstock sourced from waste collection processes and helps to boost the industry's already high circularity. The deterioration that the fibre undergoes during the course of its use, however, prevents the cycle from being closed entirely, hence requiring virgin fibres to be introduced into the papermaking circuit. While at first glance the fibre's "transience" may seem to restrict its circularity, it is worth pointing out that once the fibre has reached the end of its service life, it is still a biomass that can play a role in the wider and more complex natural carbon cycle.

That said, we should not lose sight of the fact that no design can be successful without giving careful consideration to the type of content the packaging is due to hold, and its relevant characteristics, which is key to ensuring the packaging fulfils its functions to the greatest extent. Moreover, aspects such as consumer safety and fulfilment of regulatory requirements are equally important priorities.

Lastly, we must stress that the following guidelines should be regarded as localized, pertaining as they do to the current situation in Italy and relevant technology. Consequently, the document may be revised and updated to reflect advances in technology (in terms of recycling processes), radical innovations (in terms of products), or more stringent regulations affecting the recycling chain for packaging made predominantly from paper.

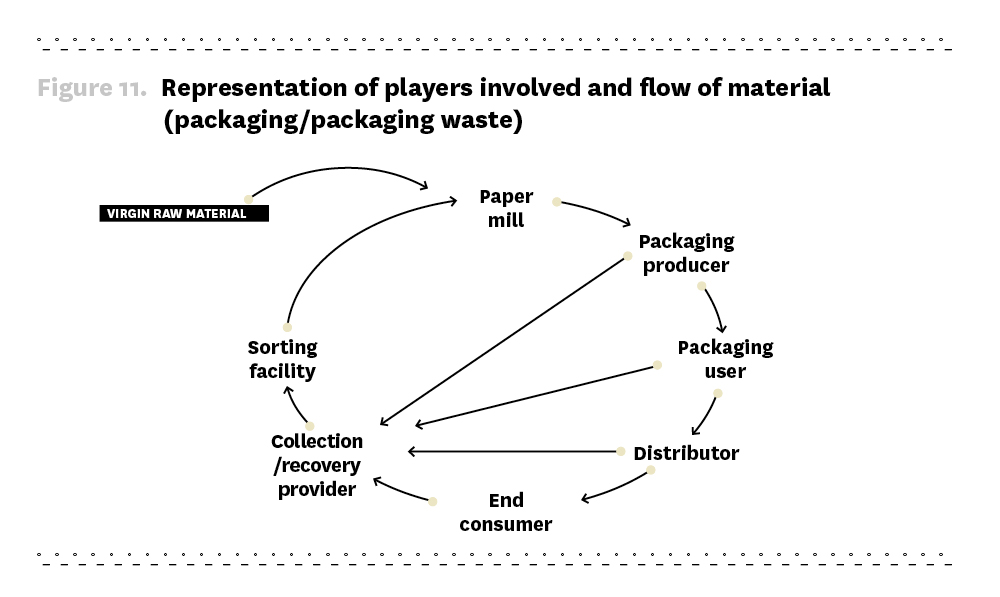

The players in Italy's recycle chain

We cannot talk about packaging without first describing the various players who interact with it during its life cycle. As we can see from Figure 4, there are multiple parties involved and they generate a flow of material - in terms of products and waste - that certainly highlights the circularity of the paper world. It is also essential to point out that, this being a chain of business relationships, each player responds to requests submitted by other players. By way of example only, we could cite the case of producers of packaging requesting paper mills to provide the raw material with specific properties in terms of quality.

Below, therefore, we will be describing the various players, attempting to explain the requirements that affect the design of packaging made predominantly from paper.

RAW MATERIAL PRODUCER

In the case we have analysed, the raw material producer is the firm in the business of making paper intended for producers of packaging. In the paper world, the raw material producer is the paper mill.

Depending on their intended output, paper mills use both virgin material and recycled feedstock in the production of raw material. Paper mills, though, are also companies responsible for the last stage in the paper-based packaging's life cycle, namely the recycling process (for a more detailed description, refer to the Mill recycling process section in chapter three). The packaging's design has a great impact on the actual processability of the material at the end of its life and on its recycling yields, especially when it comes to the presence of non-paper materials and accessories in the packaging, and the configuration of layers in composite materials.

These critical factors are linked to the fact that anything that is not paper is not going to become paper, quite the contrary: it results in process waste (so-called pulper rejects) that is hard to handle and manage.

PRODUCER OF PACKAGING

Once we have the raw material, it is generally converted by producers into a semi-finished product, to start with, and then packaging. Producers of packaging are suppliers of packaging materials, manufacturers, converters and importers of empty packaging and packaging materials.

Some companies purchase raw materials (or semi-finished products) to produce packaging designed to contain goods manufactured by these same companies, in which case we have so-called "self-producers".

Producers of packaging, when procuring raw material, are mainly interested in the quality of the raw material used and in the technological limits of the semi-finished products' machinability.

RAW MATERIAL USER

The packaging user is the company that purchases packaging in order to fill it with goods manufactured by that same company.

The user, therefore, is the player who has the most say in defining the technical and printing specifications of packaging destined to become the instrument used to deliver their goods (products they have manufactured) to the market.

Clearly, the user's focus and demands will differ depending on whether the paper-based packaging is due to be used as tertiary, secondary or primary packaging for the product it is tasked with delivering to the market.

For tertiary packaging, the focus will mainly be on mechanical properties, namely stiffness and the ability to absorb impact. Secondary packaging, in addition to the above-mentioned properties, will also be shaped by other aspects associated with technological properties. Lastly, for primary packaging, the greatest focus will be on chemical and physical properties, which must be consistent with the content the packaging is due to hold, with how it needs to be protected, how it will be used and, in addition, how it can adequately deliver on the "aesthetic" front in line with the brand.

DISTRIBUTOR

The distribution chain includes logistics, traders and supermarkets and retail chains, namely the series of activities concerned with the storage, transport and distribution of the packaged product to the points of sale.

While still fairly limited in Italy, the e-commerce market is growing and stands out from the retail system in that it takes the point of sale virtual, making it a web-based portal.

Distributors are concerned with various packaging performance characteristics that are key to the efficiency of their operations, including:

- Guaranteed production protection

- Lengthy shelf life, both for the packaging and for the contents in order to be able to manage storage and transport time frames

- Optimizing the number of units contained

- Optimizing overal dimensions for transport purposes.

END CONSUMER

The end consumer is the person who purchases or imports packaging or packaged items or goods for their own use, and not for the purpose of carrying out their business.

Consumers make their preferred product selection when purchasing, and use the item purchased, disposing of the packaging, which thus becomes waste to be sent off to the correct recycling chain.

For the packaging to fulfil all its functions properly as the product is being used by the consumer, it is essential it provide clear communication, efficient transport, and protect and store the products correctly.

COLLECTION/RECOVERY PROVIDER

This refers to all activities involved in collecting waste, whether municipal solid waste or waste from the commerce and industry circuit.

On the municipal solid waste collection front, it is typically local authorities and/or city-owned companies who are responsible for collection; while on the commercial and industrial front - in addition to a number of city-owned companies that have become integrated in the supply chain - there are private players, too, some of whom even operate nationwide across Italy. The profit that all these players stand to make is linked to the quantity and quality of the separated waste whose collection they organize, on which they depend to maximize earnings that come from the prices paid by ANCI-CONAI, i.e. the market value of said waste.

Since the activities are associated mainly with the physical handling of waste by means of a special organizational/structural system, this player's main requirements are:

- Reduced bulk of packaging waste

- Easy of campaction

SORTING FACILITY